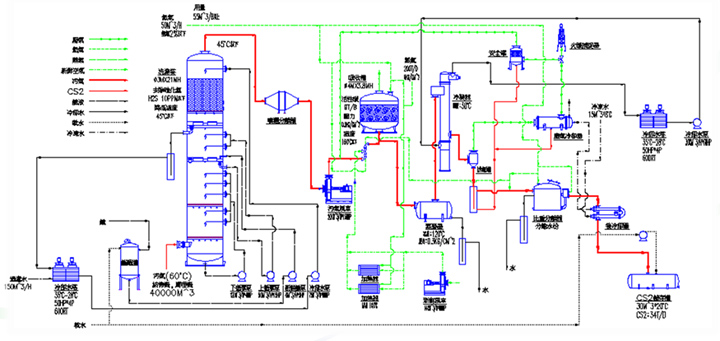

The highly concentrated waste gas CS2 for recycling treatment is partially from the double-bath tank, drafting machine, cutter, liquid workshop and villus trough. Gather and enter the washing tower for rear treatment.

1. Washing Process:

Contact with the spraying lye and then remove the H2S in the waste gas.

To guarantee the H2S content is below 15ppm before entering the absorption tank, the exhaust from the alkali tank is delivered to the bottom, sprayed with circulating lye to remove HS2, then cooling down with filtered water, and is sent to the absorption trough after liquid removal by the sparging separator.

2. Adsorption Process

Each absorption trough contains measured active carbon. When the active carbon reaches saturated condition, it begins desorption. Fill in nitrogen before desorption for safety, and the 0.4MPa steaming is adopted for the procedure. After desorption, using hot air to dry the active carbon, and cool it with cold air.

The waste gas delivered in the absorption trough has a small quantity of H2S, and the adsorbed H2S is thus oxidized and generate sulfide and sulfuric acid through the process of desorption and drying, blocking and inactivating the active carbon. Therefore, the desulfuration and deacidification to the active carbon must be performed regularly.

3. Condensation and Recycling

The desopted CS2 and steaming mixed air enter the condenser through the evaporator. The circulating filtered water is cooled in the cooling tower and being recycling used as cooling water. After condensation, the liquid CS2 goes through the exhaust tank into the specific gravity separator, using the different specific gravity of CS2 and water to conduct separation. A small amount of partially condensed gas is sent to waste gas cooling for the second cooling. The cooling media that the waste gas cooling used is chilled water. The uncondensed gas goes through the safety can and return to the absorption trough for further absorption, while the condensed CS2 enters the specific gravity separator. The specific gravity separator is equipped with an after-cooler, which enhances the stability of liquid CS2, and finally enters the CS2 storage trough.

The waste gas treatment process is complex, and the environment is inflammable and explosive. Technical operation is mostly auto-controlled, thus to guarantee the production safety.